"Diversität leben - eigentlich ist das für uns alle Alltag. Aber diese Diversität wollen und müssen wir auch im Arbeitsleben noch konsequenter abbilden. Davon profitieren wir, Diversität ist heute Grundvoraussetzung für Erfolg!" Das Statement kommt von Herzen. Sehen Sie selbst!

Despite setbacks due to the two world wars, economic development in Germany during the final decades of the nineteenth and first of the twentieth century was characterised by an enormous innovative economic strength, and a spirit of renewal and change. The TÜV technical inspection associations and their engineers were in the slipstream of every new discovery. Even if they were not strictly speaking inventors, they were nevertheless indispensable when it came to making these inventions suitable for widespread, safe and economically efficient use.

By testing and certifying, the TÜV associations assisted the spread of electricity, just as they supported intensified mechanisation and the development of mass production. TÜV engineers and laboratories were often involved from the get-go in the emergence of new industries, where industrial production was based on research activity, and where findings in chemistry and physics in particular were made commercially exploitable on a large scale.

From the very beginning, TÜV’s predecessor, the Essen Mines Association (Zechen-Verein Essen), was concerned not only with steam boilers but also with lighting and ventilation, i.e. mining technology of all kinds. Starting in 1905, responsibility for elevators, motor vehicles and materials handling equipment in the broadest sense was added by official decree, along with pressure vessels for gases, mineral water apparatus, acetylene plants and electrical installations in general. In 1909, Rheinische DÜV Düsseldorf/Essen e.V. was entrusted with the inspection of all non-mining industrial plants. From 1930 onwards, non-destructive testing of systems and installations was in particular demand.

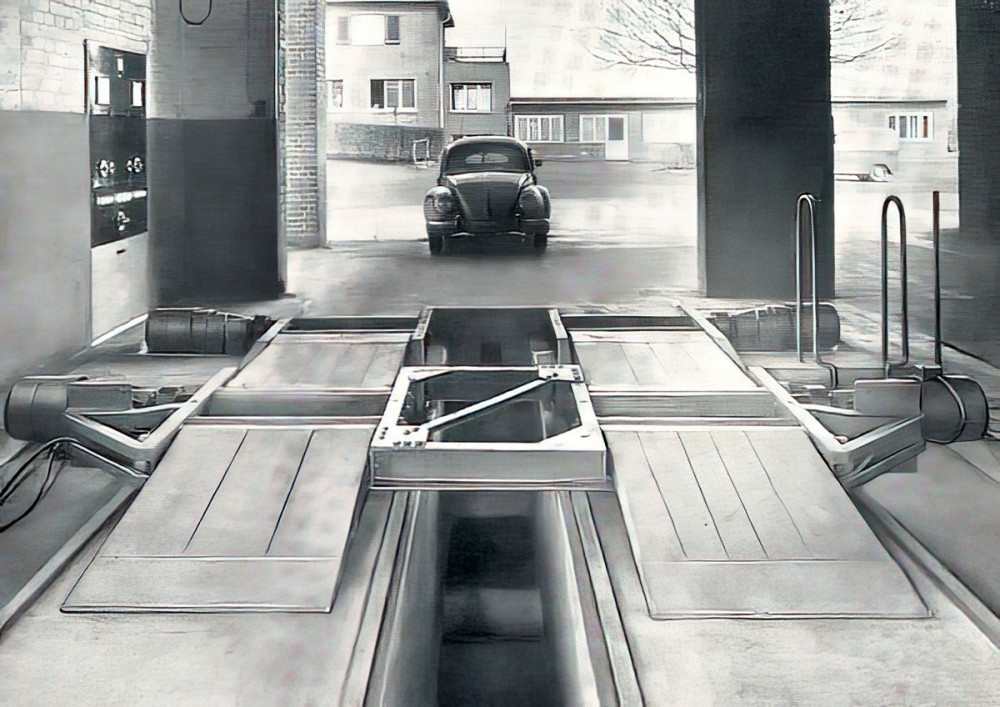

Of significance for private individuals was the change in 1938 when the previously voluntary inspection of motor vehicles and driver tests became compulsory. The classic TÜV licence plate inspection sticker did not come into being until 1961; it served as documentation and a reminder of the vehicle owner’s obligation to arrange a timely inspection, and later became a trademark. However, this is one branch of activities where the TÜV associations’ impact grew the most. In the 1950s, the Automotive Lab (Kraftfahrzeuglaboratorium) was established. Later it became the Institute of Vehicle Technology, until today an important partner to the automotive industry and its suppliers.

From 1959, expertise in the peaceful use of nuclear energy was steadily expanded. TÜV Essen set up a central department for large power stations, mining, and construction and assembly supervision. The TÜV associations rode the wave of success in the steel and coal industries, for example by supervising refineries or the construction of oil and gas pipelines. The construction sector also developed strong traction, especially power plant construction. Important growth drivers for the TÜV associations were the certification of construction, calculation and assembly documents, and of welding and other construction or production processes, as well as the supervision of construction and assembly activities.

Occupational safety and environmental protection also gained importance in the 1970s, and a laboratory was established for mechanical-technological materials testing as well as chemical and physical testing.